Umshini Wezimayini-Izingxenye Zokugaya Izingxenye-Izigayi Zomshini

Incazelo Yomkhiqizo

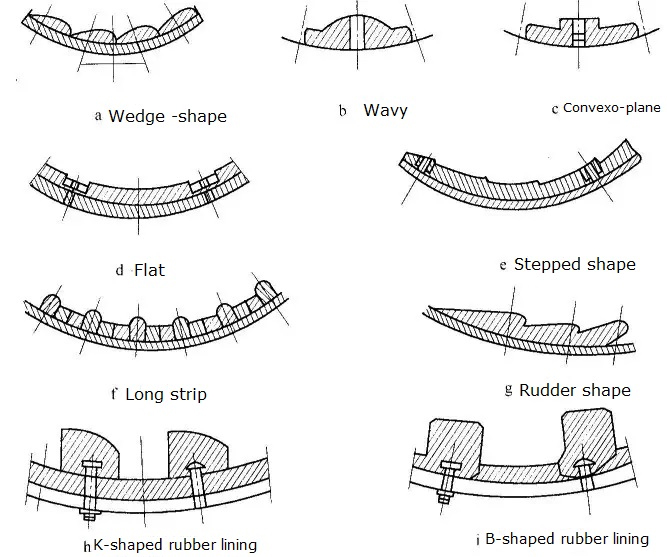

Ukuze uvumelane nezidingo zezifunda ezahlukene zokusebenza (ukuchoboza noma ukugaya kahle), ukuma kwe-liner kuhlukile. Uma ukuchotshozwa kuwumsebenzi oyinhloko, kuyadingeka ukuthi i-liner ibe nekhono elinamandla lokusunduza emzimbeni wokugaya, futhi i-liner kufanele ibe nokumelana nomthelela omuhle. Lapho ukugaya okuyinhloko kulungile, ukugqama kwe-liner kuncane kakhulu, umphumela wokusunduza womzimba wokugaya ubuthakathaka, umthelela mncane, umphumela wokugaya unamandla, futhi i-liner iyadingeka ukuze ibe nokuphikiswa okuhle kokugqoka. Inqubo yokukhiqiza eklanyelwe ethuthukisiwe, okuhlanganisa nesistimu yokulinganisa isisindo esithandweni somlilo, isistimu yokulawula ukushisa okugcwele ikhompuyutha, isistimu yokupholisa ecisha ngokushesha, njll, okuyizisekelo zesiqinisekiso sekhwalithi yemikhiqizo yethu.

Inkampani yethu ingesinye sezisekelo ezinkulu zokukhiqiza zensimbi ezingagugi e-China, ngokukhiqizwa konyaka okungamathani angama-40,000 ensimbi ehlukahlukene engagugi, okuhlanganisa insimbi ephezulu ye-manganese, insimbi eyingxubevange, insimbi ekhonjiwe, insimbi yokusansimbi ephezulu ye-chromium, i-chromium cast iron emaphakathi, njll., i-WUJ yamukela imidwebo eyenziwe ngokwezifiso futhi ingahlela ochwepheshe ukuthi benze ukulinganisa ngokomzimba kanye nokwenza imephu esizeni.

Izinto ezisetshenziswayo (zingakhiqizwa ngokwezidingo zamakhasimende)

| Isici | C | Si | Mn | P | S | Cr | Ni | Mo | Al | Cu | Ti |

| Mn13 | 1.10-1.15 | 0.30-0.60 | 12.00-14.00 | <0.05 | <0.045 | / | / | / | / | / | / |

| Mn13Mo0.5 | 1.10-1.17 | 0.30-0.60 | 12.00-14.00 | ≤0.050 | ≤0.045 | / | / | 0.40-0.60 | / | / | / |

| Mn13Mo1.0 | 1.10-1.17 | 0.30-0.60 | 12.00-14.00 | ≤0.050 | ≤0.045 | / | / | 0.90-1.10 | / | / | / |

| Mn13Cr2 | 1.25-1.30 | 0.30-0.60 | 13.0-14.0 | ≤0.045 | ≤0.02 | 1.9-2.3 | / | / | / | / | / |

| Mn18Cr2 | 1.25-1.30 | 0.30-0.60 | 18.0-19.0 | ≤0.05 | ≤0.02 | 1.9-2.3 | / | / | / | / | / |

| Nezinye izinto eziphakeme ze-chromium nezinto zensimbi ye-alloy ozidingayo | |||||||||||