The sand from the general sand making machine needs to be cleaned by the sand washing machine in order to be cleaner and have better quality. The commonly used sand washing equipment includes spiral sand washing machine and wheel sand washing machine.

Whether it is a spiral sand washing machine or a wheeled sand washing machine, there is a disadvantage, that is, the sand is not clean after sand washing, and the loss of fine sand is serious, especially ultra-fine sand. According to everyone’s feedback, this situation is quite common, so how to solve it? To solve the above problems, you can try the following two solutions:

1. Sand washing machine + dewatering screen means that a dewatering screen is installed after the sand washing machine equipment. The sand output of the sand washing machine is relatively large, so the purity of the sand may not be guaranteed. After a dewatering screen is added, the sand delivered to the conveyor belt will be relatively clean. The main function of the dewatering screen is dehydration, desliming, desliming, equipment low inclination large linear vibration, combined with the electromagnetic vibration net to clean the sand on the screen, the sand is discharged from the screen, the water is discharged from the screen into the tailings pump tank.

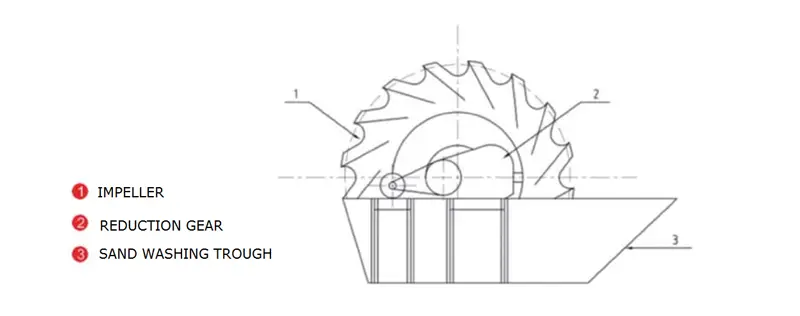

This method does not use a sand washing machine, and directly uses a sand washing and recycling machine. It is composed of separator, dewatering screen, impeller separator, reducer, slag pump, cleaning box and other components, with the dual functions of sand washing machine and fine sand recovery machine.

Sand washing and recycling machine working principle:

The sand-water mixture enters the cleaning tank, is separated by the impeller separator, and then enters the lower dewatering screen for dewatering treatment. The wastewater from the cleaning box (containing a large number of fine sand, mud, dust and other impurities) is transported to the separator by the slag pump, and then the fine sand after centrifugal classification and concentration is discharged into the upper layer of the dewatering screen through the settling nozzle. The waste water, mud, dust, impurities, etc. in the cleaning box shall be discharged into the high level and returned to the water tank through the overflow port of the separator. The finished material shall be coarse sand on the upper level, the finished material shall be fine sand on the lower level, or the coarse and fine sand shall be mixed out.

The above two methods can greatly improve the purity of the sand and reduce the loss of fine sand, if you happen to have this confusion for reference.

Post time: Jan-09-2025