1, when it comes to the complex pendulum jaw break, it is necessary to mention the simple pendulum, the two are divided by pressing the jaw movement trajectory, the simple pendulum jaw break has two axes and two elbow plates, one of which is eccentric shaft, driven by the motor, the moving jaw does reciprocating movement to the fixed jaw, the material thus extruded, the broken material is discharged from the crusher by its own weight.

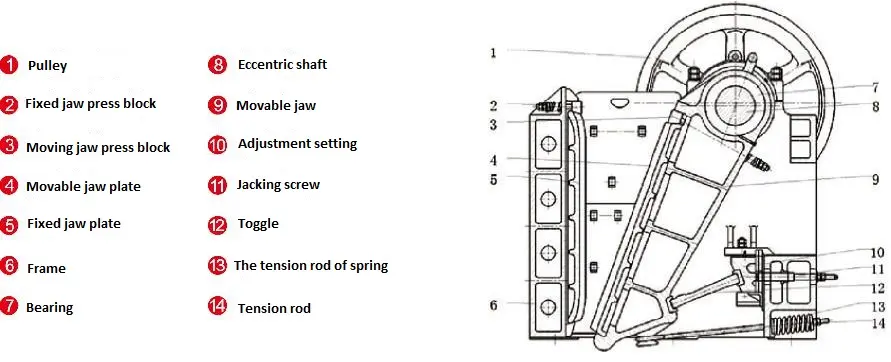

The compound pendulum jaw has an eccentric shaft and a elbow plate, and the rotating eccentric shaft drives the fixed jaw, so that the moving jaw moves reciprocally to the fixed jaw, and the movement track changes from the circle to the ellipse from top to bottom. In addition to being crushed, the material is also subjected to a downward cutting force, so that the material is discharged from the crushing chamber by its own weight, and the downward cutting force also speeds up the material’s passing speed.

The advantage of simple pendulum crusher is that the liner wear is far less than the pendulum, in addition, other aspects are worse than the pendulum, such as low production capacity, large equipment weight, so basically no longer used. At present, more on the market are pendulum jaw break.

2, vibrating jaw crusher Vibrating jaw crusher is the use of unbalanced vibrator to produce high frequency vibration and centrifugal inertia force to achieve the crushing of materials. It consists of a frame, two symmetrical jaw, unbalanced vibrator, jaw plate elastic suspension device and other main components.

The jaw plate is suspended from the frame, and a pair of unbalanced vibrators are driven by a motor to rotate relative to each other. The transmission device of the unbalanced vibrator is connected with the moving jaw to reduce the impact load on the transmission device and its bearing.

The jaw break does not need to be equipped with a large foundation, suitable for installation in the open pit mobile crushing unit and underground crusher chamber, batch feeding, can also be filled to feed, greater than the size of the discharge port of the material can automatically pass, no blocking material, no safety device. It can break hard materials, and can also handle viscous materials containing more fine particles and high moisture content.

3, jaw crusher Jaw crusher is based on the standard rotary crusher development. Close the feed port on one side of the rotary crusher and enlarge the feed port on the other side.

The feed port is usually equipped with a toothed liner and forms an initial crushing zone with the upper frame. The material after the initial crushing is further broken in the lower part of the crushing chamber to achieve the required particle size.

The jaw rotary crusher has the function of jaw breaking and rotary crushing in two stages, which can handle larger materials than the same specification rotary crusher, so the jaw rotary crusher has a larger crushing ratio, and it is not easy to block in the feeding area.

4, the low jaw crusher and the traditional compound pendulum jaw crusher is the opposite, the moving jaw and eccentric shaft are located on both sides of the crushing chamber and the fixed jaw, the eccentric shaft is driven by the motor through the triangular belt, and the rotation of the eccentric shaft is transmitted to the outer moving jaw through the side plate, so that the moving jaw is periodically swung. The material falling into the crushing chamber composed of moving jaw and adjustable jaw is crushed by extrusion, splitting and bending, and discharged by the discharge port.

The separation of the moving jaw and the connecting rod makes the movement of the connecting rod no longer restrict the movement characteristics of the moving jaw. As long as the mechanism parameters are changed, the moving jaw movement trajectory can be adjusted, so as to obtain the ideal moving jaw movement characteristics, so that the horizontal stroke of the moving jaw is large, the vertical stroke is small, the crushing efficiency is high, and the liner wear is less. Low shape, low feeding height, reduce the crushing operation space, suitable for installation in the underground crusher chamber. By adjusting the size of the bracket and adjusting the weight of the jaw, the size of the discharge port can be conveniently adjusted.

5 Double cavity jaw crusher

(1) The SX series double-acting jaw crusher developed by Shenyang Gold University replaces the single-acting jaw of the double-acting jaw crusher with two synchronous reverse relative motion, and replaces the positive inclination structure with the main hinged four-bar mechanism with the thrust plate as the negative inclination Angle. Increase the horizontal stroke of the moving jaw and improve the crushing force. The machine has the advantages of high processing capacity, large crushing ratio, low energy consumption and small liner wear by adopting deep crushing chamber, variable Angle, high speed and large momentum transmission.

(2) The PSS double-cavity double-action jaw crusher developed by Beijing General Research Institute of Mining and Metallurgy has a unique single-turn double-ear bearing seat inset dynamic jaw structure, and one shaft drives two dynamic jaws at the same time, making full use of the energy storage effect of the empty stroke of the crusher, and improving the processing capacity. Negative support, zero suspension, high depth curve type crushing chamber, large crushing ratio, fine product particle size, long liner life, convenient adjustment of discharge port.

(3) The two crushing chambers of the double-cavity jaw crusher developed by the Central South University of Technology are symmetrically arranged with the eccentric shaft as the center, and there is a movable tooth plate on each side of the moving jaw, which respectively forms two crushing chambers with the fixed jaw plate. It is an inverted four-bar mechanism, with the characteristics of small snapping Angle, deep crushing chamber, and long parallel zone near the discharge port, so that the material is broken fully, the product particle size is fine and uniform, the processing capacity is large, the liner wear is small, and the tooth plate life is long.

Although there are many types of jaw crusher, and has more than 100 years of development history, but the most used is still the compound pendulum jaw crusher, many well-known companies at home and abroad only produce this series of jaw crusher, is also the most used type on the market. We often say that the jaw fracture is generally not specifically specified are complex jaw fracture.

Post time: Oct-14-2024