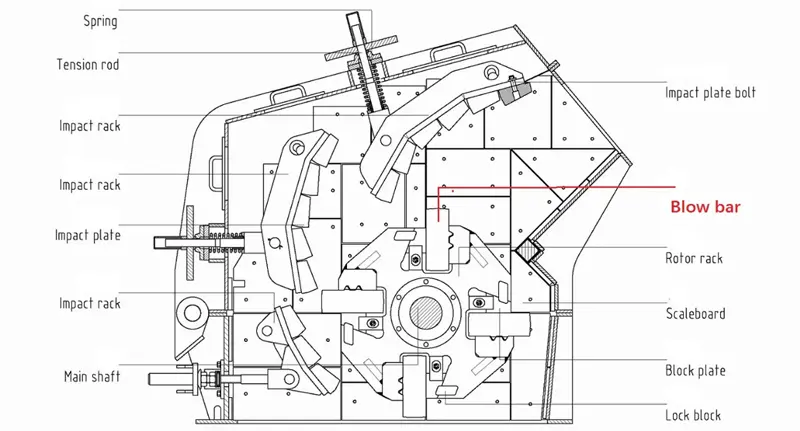

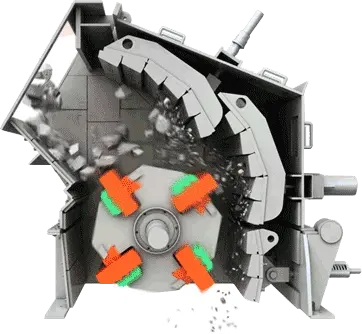

Impact crusher is widely used in construction, road and bridge, water conservancy and other industries to manufacture suitable specifications of stone for concrete, cement and other materials production. However, the impact crusher has some easily damaged parts, mainly three: plate hammer, liner plate, bearing.

First, the impact crusher common wear parts replacement and repair methods

When the impact crusher replaces the wearing parts, it is first opened and then put on the shelf. When in use, first remove the connecting bolts between the rear shelf and the middle box, and then twist the hexagon head part of the clamshell device with a wrench, and then slowly open the shelf. At the same time, the rear frame can be suspended by the hanging device above the frame. Repeat the above process, that is, after closing the shelf.

1, the replacement of the hammer: the hammer should be adjusted or replaced in time when it is worn to a certain extent to avoid damage to fasteners and other parts.

2, impact crusher liner replacement: open the back cover, remove the cotter pin, slotted nuts, bolts used to fix the impact liner, you can replace the worn impact liner. If installing a new counter liner, reverse the above steps immediately.

3, the bearing temperature of the impact crusher is too high or too little grease: check whether the grease is excessive; Dirty grease: Replace grease after clear bearing; Bearing damage: The replacement of bearing impact crusher plays a key step in the sand production line, in the process of use, we should timely maintenance and repair, the problem in the bud, do not be penny wise and pound foolish, the loss is more serious, to ensure the normal and stable state of sand production line.

Second, reduce the hammer crusher hammer head wear method

Selecting a reasonable speed, the impact hardening degree of the hammer head can be improved quickly in the early working period; The grate structure is improved to make the discharging material smooth; Often adjust the gap of each part to keep it within the appropriate range. These help to reduce the wear of the hammer. Through the analysis of influencing factors of hammer crusher wear hammer head, according to different influencing factors, different anti-wear measures should be adopted to extend the service life of hammer head, reduce material consumption and downtime, to reduce costs and improve the purpose of enterprise economic benefits.

Post time: Mar-19-2025