High efficiency anti-blocking screen: The “artifact” to solve the problem of vibration screen plugging

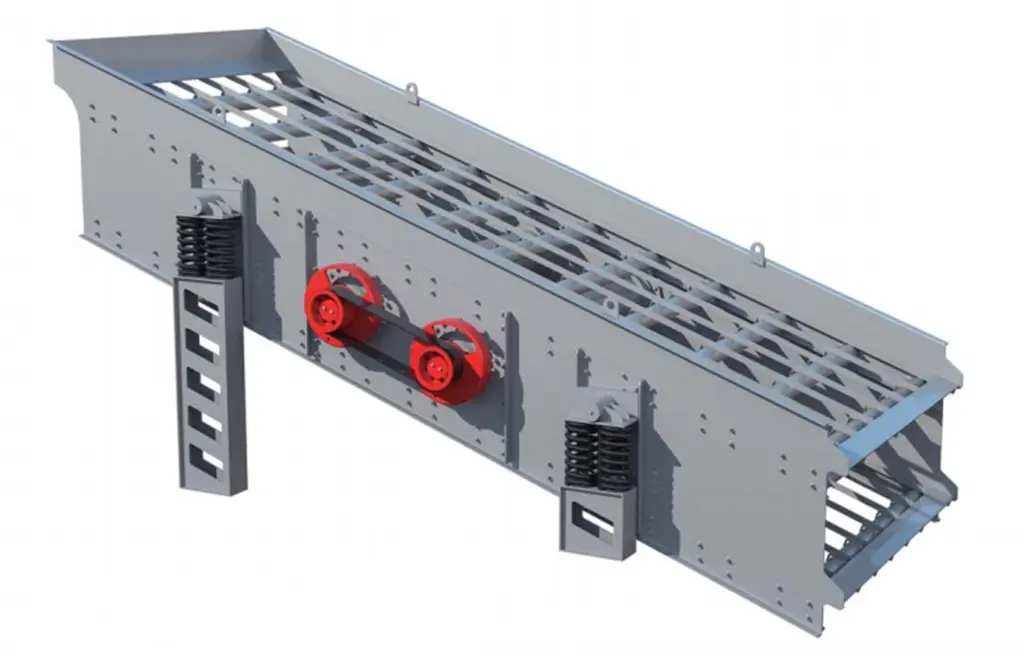

In industrial production, vibrating screen is a common material screening equipment, widely used in mining, chemical, food, pharmaceutical and other industries. However, the problem of vibration screen plugging has always been a “big problem” that has plagued enterprises. Plugging will not only reduce screening efficiency and increase equipment maintenance costs, but also may lead to production interruption and affect enterprise efficiency. Today, with the advancement of technology, efficient anti-blocking screens have come into being, providing the perfect solution to this problem.

Why is the screen easily blocked?

Screen holes can be blocked for a variety of reasons. First of all, the characteristics of the material are the key factor. For example, viscous materials, materials with high water content or materials with irregular particle shapes are more likely to accumulate in the screen holes, leading to blockage. Secondly, the material and structure of the screen itself will also affect the plugging situation. The traditional screen size is small, easy to be blocked by fine material particles; The insufficient wear resistance and corrosion resistance of some screen materials will also lead to screen mesh deformation or damage, further aggravating the phenomenon of plugging.

Advantages of high efficiency anti-blocking screen

Efficient anti-blocking screen through innovative design and material, effectively solve the problem of traditional screen plugging. First of all, this screen adopts a special pass structure, such as rectangular holes, triangular holes or trapezoidal holes, which can better adapt to the characteristics of different materials than the traditional round or square holes, reducing the accumulation of materials in the holes. Secondly, the material of the anti-blocking screen is specially treated to have higher wear resistance and corrosion resistance, which can extend the service life of the screen and reduce maintenance costs.

In addition, some anti-blocking screens are also equipped with automatic cleaning devices. For example, through a vibrating spring or pneumatic cleaning system installed on the screen, the blockage in the hole can be automatically removed during the screening process, ensuring that the screen always maintains good permeability. This automatic cleaning function not only improves the screening efficiency, but also reduces the frequency and labor intensity of manual cleaning.

Performance in practical application

In actual production, the effect of high efficiency anti-blocking screen is very significant. Taking the mining industry as an example, after a mining enterprise uses a high-efficiency anti-blocking screen, the screening efficiency is increased by 30%, and the equipment downtime is reduced by 50%. In the chemical industry, when a company used an anti-blocking screen to deal with high-viscosity materials, the plugging problem was effectively solved and production efficiency was greatly improved. These cases fully prove the powerful advantages of high-efficiency anti-blocking screens in practical applications.

Select the appropriate anti-blocking screen

Although the advantages of high-efficiency anti-blocking screens are obvious, the selection still needs to be considered according to the specific application scenarios and material characteristics. For example, for materials with high water content, you can choose an anti-blocking screen with a drainage hole; For materials with irregular particle shape, a screen with a more complex pass can be selected. At the same time, it is also necessary to pay attention to the material and thickness of the screen to ensure that it can adapt to different working environments.

In short, the high-efficiency anti-blocking screen is the “artifact” to solve the problem of the blocking hole of the vibrating screen. It can not only improve screening efficiency, reduce equipment maintenance costs, but also bring higher economic benefits to enterprises. If your vibrating screen is also facing the problem of blocking holes, you may wish to try this efficient anti-blocking screen to make the production smoother!

Post time: Mar-05-2025