Mining Machine–WJG Series Jaw Crusher

Performance Features

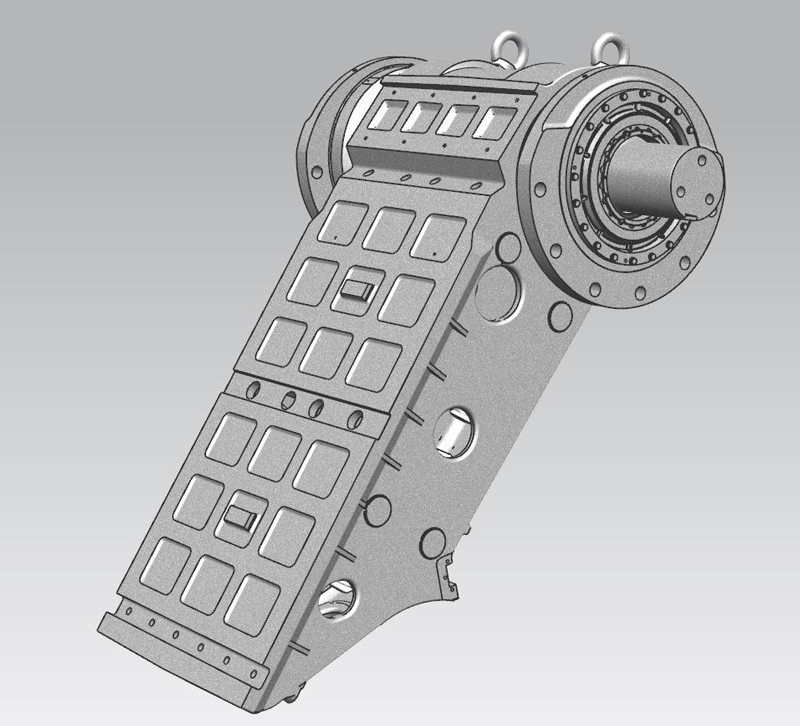

1. Modular design, no welding frame structure, high impact resistance.

2. Integrated motor installation, saving installation space.

3. Superior crushing cavity design, optimized engagement angle and movement characteristics, help to improve the crushing ratio.

4. Convenient adjustment of the discharge opening and the adoption of the hydraulic wedge adjustment method make the operation simpler and safer.

5. Having a centralized lubrication system that help to save maintenance costs and maximize the operating time.

6. The use of high-performance forged alloy steel main shaft,high-quality heavy-duty bearings, more reliable use.

7. Easy to maintain and install, low operating cost.

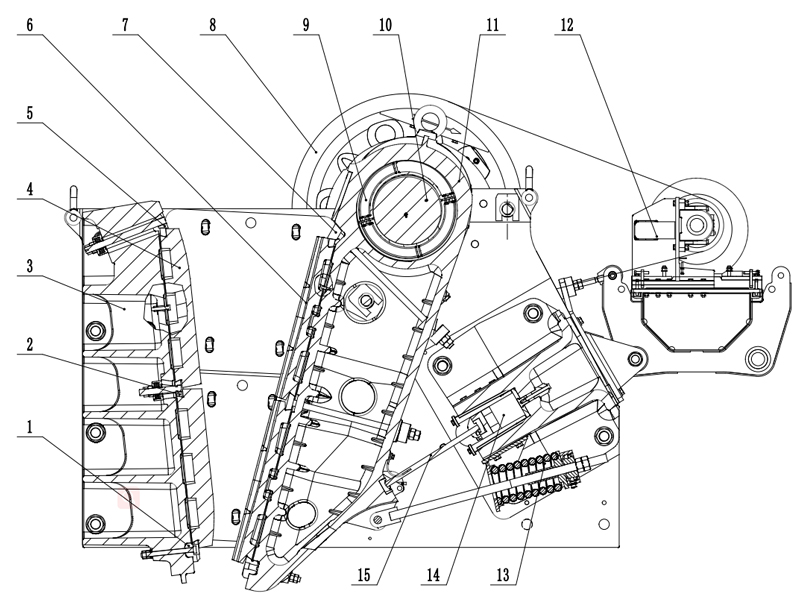

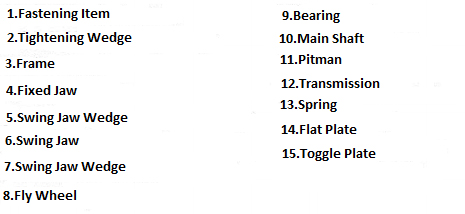

Working Principle

Jaw crusher mainly includes a base, fixed jaw, moving jaw, eccentric shaft, jaw plate, moving jaw plate is fixed on the pitman by connecting the bolt rod. Moving jaw plate is provided with a cheek plate on both sides of the moving jaw plate, the upper end of the moving jaw plate is arranged on the eccentric shaft, between the moving jaw plate is provided with an eccentric bearing cavity. Moving jaw plate is higher than the fixed jaw plate about 80-250mm, simple and reasonable structure, The high moving jaw plate has a good protection effect on the moving jaw and the bearing space, and ensures the smooth feed, avoids the phenomenon of the material stuck, safe and reliable. The movable jaw bearing chamber has good sealing, good operation performance, no oil leakage, low noise, stable operation, energy saving effect, which is conducive to popularization and application.

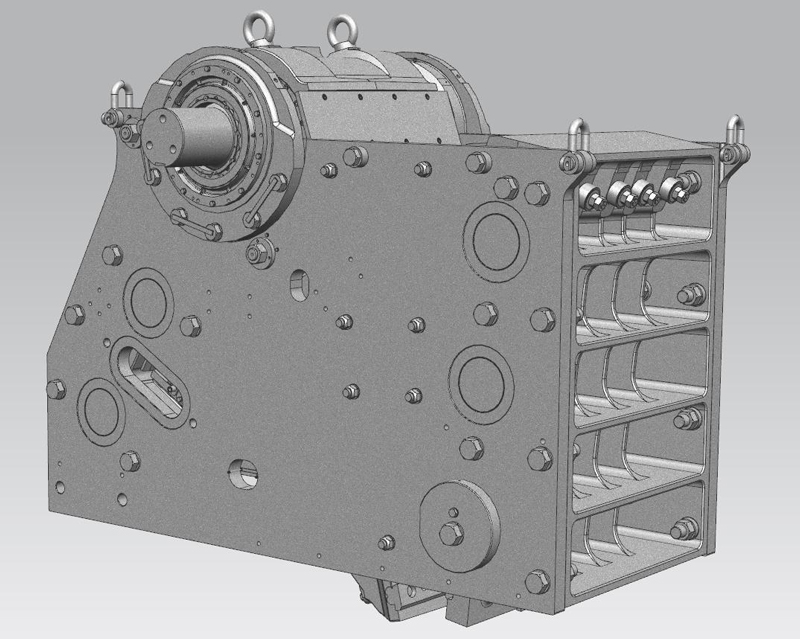

Technical Specification

| Specification and model |

Feed Size (mm) |

Motor Power | Discharge Gap (mm) | Speed (r/min) |

|||||||||

| Capacity (mm) | |||||||||||||

| (kW) | 80 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 300 | ||||

| wJG110 | 1100X850 | 160 | 190~250 | 210~275 | 225-330 | 310-405 | 370-480 | 425-550 | 480-625 | 230 | |||

| wJG125 | 1250X950 | 185 | 290-380 | 350-455 | 415-535 | 470-610 | 530-690 | 590-770 | 650-845 | 220 | |||

| WJG140 | 1400X1070 | 220 | 385-500 | 455-590 | 520-675 | 590-765 | 655-850 | 725-945 | 220 | ||||

| wJG160 | 1600X1200 | 250 | 520-675 | 595-775 | 675-880 | 750-975 | 825-1070 | 980-1275 | 220 | ||||

| wJG200 | 2000x1500 | 400 | 760-990 | 855-1110 | 945-1230 | 1040-1350 | 1225-1590 | 200 | |||||

Note:

1. The output given in the above table is only an approximate value to illustrate the capacity of the crusher.

2. Technical parameters are subject to change without further notice.